What you'll find in this article

Defining Quality Management

Quality Management is a concept that has been widely adopted by modern businesses to address the need to continually enhance operational quality and productivity. The idea behind quality management is that goods and services would meet a certain standard of consistency in their delivery.

There are four basic components to quality management:

These concepts have evolved to become internationally renowned standards of practice. The most commonly known standards today are ISO 9000 and Six Sigma.

Basics of ISO 9000

ISO 9000 is a well-established international standard for quality management systems in almost every industry. A theoretical set of requirements was developed in 1987 by the International Standardization Organization. Since then, it has evolved into a practical, process-oriented approach to assessing the effectiveness of quality management systems.

ISO 9000 defines that quality management systems should:

An ISO certification should assure that acceptable systems, processes, and procedures are in place to ensure that product and service quality are being met. Providing the basis for documenting knowledge of processes serves as a fundamental training mechanism, allowing for an effective revision of policies and procedures to ensure the most reliable training standards possible.

Basics of Six Sigma

Developed by Motorola in 1986, Six Sigma aims to reduce mistakes and defects below a standardized rate of 3.4 per million opportunities. This is accomplished by identifying and eliminating causes of variation in businesses by focusing on developing a clear understanding of customer requirements—making it very customer-focused.

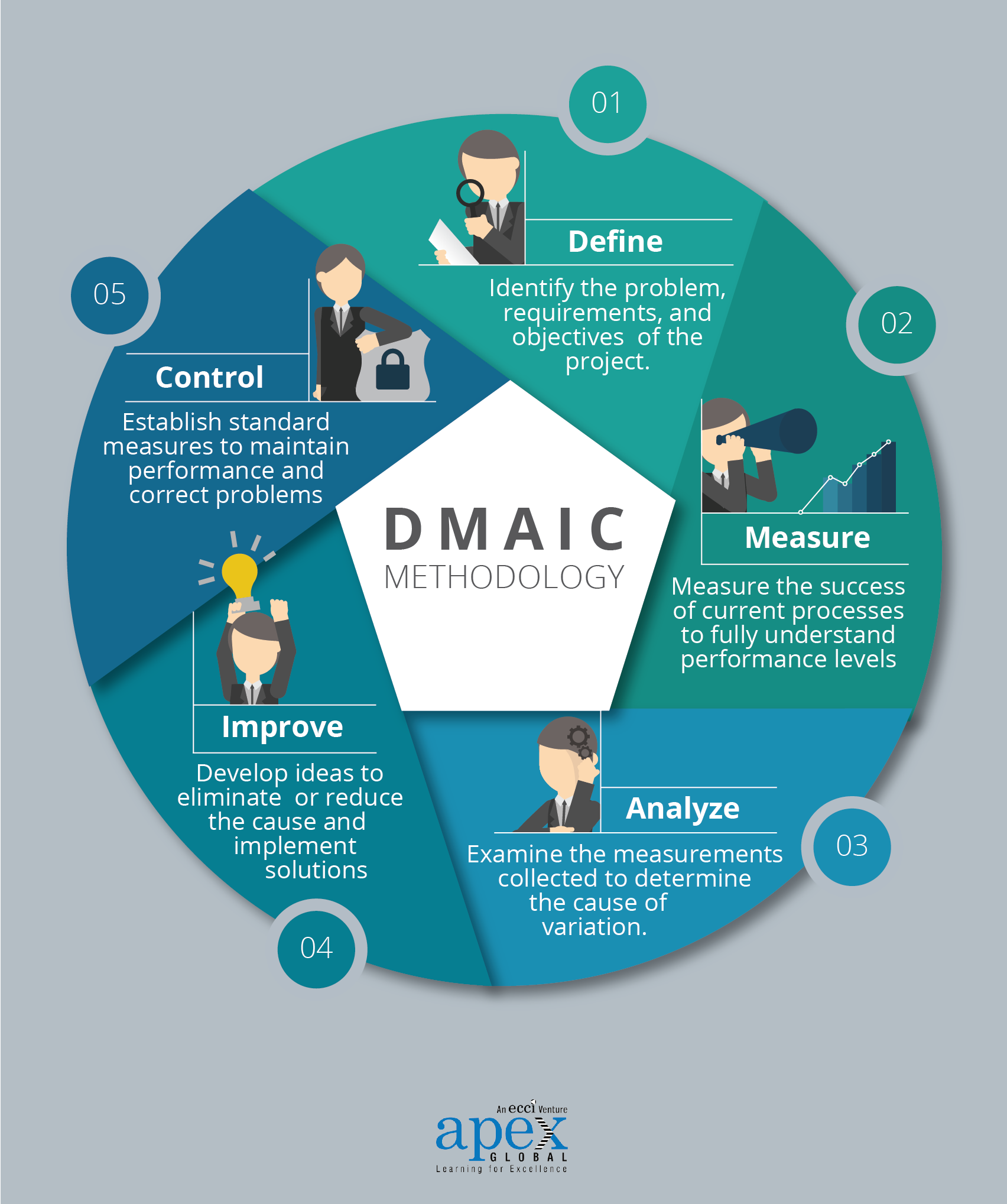

The principal of Six Sigma follows the DMAIC methodology, which is defined below:

Six Sigma’s capability to deliver significant results for businesses is widely recognized for a range of processes within any company. This applies to businesses in all parts of the world, and Six Sigma Philippines is no exception. Organizations can get certified and adopt these quality management systems themselves.

Similarities of ISO 9000 and Six Sigma

These two systems also have an underlying approach that uses a cycle for continuous improvement. Where improvements are made, this aspect allows for changes to be checked and acted upon to correct problems or cement changes that are realized. The cycles for each concept are displayed below:

Differences between ISO 9000 and Six Sigma

The main difference between the two concepts is that ISO 9000 is a shell of requirements used as the basis to develop the entirety of a business’ quality management system while Six Sigma is solely a set of tools and methods used to improve specific business processes.

ISO 9000 does not have any tools to utilize during implementation, and Six Sigma does not contain a standardized set of requirements recognized internationally. This makes ISO certification and Six Sigma certification processes differently.

The two also differ in conceptual design. Six Sigma uses the DMADV methodology, which is not equivalent to the 7-part design process of ISO 9000:

Achieving Synergy with the Two Systems

Due to the nature of their differences, ISO 9000 and Six Sigma concepts can be used to complement each other. Six Sigma methodologies can be utilized as a tool within a quality management system to meet ISO 9001 requirements.

On the other hand, the ISO 9000 framework can be used to assess a Six Sigma system. A fortunate side effect is that both approaches can become aligned when integrated together—eliminating the need to compete for resources.

Since the overall objectives of the two concepts are the same, there will be a greater likelihood of increasing quality management results on a long-term basis.

Implementing both concepts side-by-side would be wasteful without any integration. Aligning them both can help with the credibility and sustainability of a quality management system. The result is significant savings in resources—ultimately, enhancing the way that business is managed.